Silicone Rubber Impression Materials

Silicone Rubber Impression Materials

- Developed to address the drawbacks of polysulfides.

- Silicone rubbers are cleaner, more pleasant, and easier to use.

Types

- Condensation Silicones (older, conventional type)

- Addition Silicones (more modern and stable)

These are available in various colors and viscosities, often color-coded for identification.

Condensation Silicone

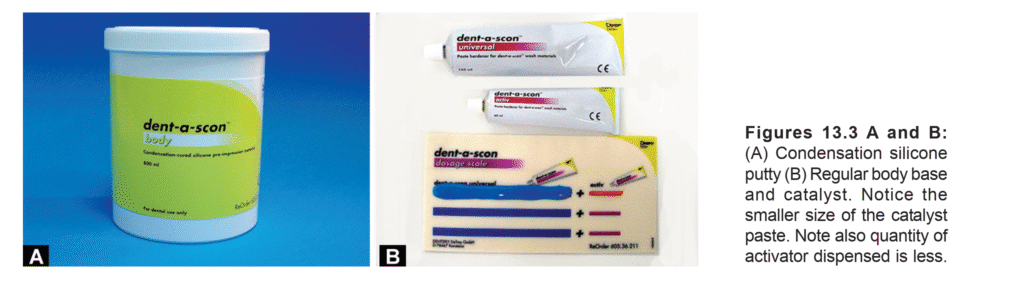

Packaging

- Pastes in tubes (base in large tube, catalyst in smaller one)

- Putty in large jars; catalyst as paste or liquid

- Available Viscosities: light, medium, and putty

Common Brands

- Sil 21, Coltex, Dent-a-scon

Composition

- Base:

- Hydroxy-terminated polydimethyl siloxane

- Fillers (colloidal silica or metal oxides): 35–75%

- Pigments

- Accelerator:

- Orthoethyl silicate (crosslinking agent)

- Stannous octoate (catalyst)

Setting Reaction

- Condensation polymerization between orthoethyl silicate and siloxane terminals

- Exothermic reaction (~1°C)

- By-product: Ethyl alcohol, which evaporates and causes shrinkage

Tray Adhesive

Contains poly(dimethyl siloxane) and ethyl silicate to bond physically and chemically to tray and impression material.

Properties

- Pleasant color and odor, though skin contact should be avoided

- Setting time: 6–9 minutes; mixing time: 45 seconds

- Excellent surface detail reproduction

- Moderate dimensional stability:

- Shrinkage from alcohol loss (0.4–0.6%)

- Immediate pouring recommended

- High permanent deformation (1–3%)

- Lower tear strength than polysulfide (~3000 g/cm)

- Stiffer and harder; requires 3 mm tray spacing

- Hydrophobic—requires dry field and careful pouring

- Electroplatable, preferably with silver

- Shelf life: Slightly shorter than polysulfides due to silicate instability

Manipulation of Condensation Silicone Impression Materials

Putty Form

- The required number of base scoops is taken.

- A small, manufacturer-recommended amount of catalyst (liquid or paste) is added.

- Mixing is done by kneading between fingers until a uniform, streak-free putty is formed.

Paste Form

- Base and catalyst are usually unequal in amount.

- The required length of catalyst paste is indicated on the mixing pad.

- Mixed with a spatula, ensuring uniformity.

Note: The catalyst paste is generally less in volume compared to the base, unlike addition silicones.

Addition Silicones (Polyvinyl Siloxane – PVS)

Addition silicones, also known as polyvinyl siloxanes (PVS), were introduced after condensation silicones. They offer superior properties, making them the most widely used elastomeric impression material today.

Packaging

- Tubes: Base and catalyst in equal-sized tubes

- Cartridges: For automatic mixing using a dispensing gun

- Putty jars: Two equal-sized plastic jars

- Automated dispensing systems: e.g., Pentamix (ESPE), which mixes and dispenses material at the push of a button

Available Viscosities

- Light body

- Medium body

- Heavy body

- Putty

Different viscosities are color-coded (e.g., orange, green, blue) for easy identification.

Common Brands

- Reprosil (Dentsply)

- Provil

- President (Coltene)

Composition

| Component | Base | Catalyst (Accelerator) |

|---|---|---|

| Polymer | Divinyl polysiloxane | Poly(methyl hydrogen siloxane) |

| Additives | Other siloxane prepolymers, fillers | Platinum salt (chloroplatinic acid), palladium (hydrogen absorber), retarders, fillers |

Setting Reaction

- Addition polymerization between vinyl groups and silane groups

- Catalyst: Platinum salt

- No by-products are produced if the mixture is balanced

- If unbalanced, hydrogen gas is released, causing air bubbles in the stone cast

- Palladium is added to absorb excess hydrogen

⚠️ Avoid sulfur contamination (e.g., from latex gloves) as it can inhibit setting. Use vinyl gloves instead.

Properties

- Pleasant odor and color

- Avoid skin contact (can cause allergic reactions)

- Excellent detail reproduction

- Setting time: 5–9 minutes

Mixing time: 45 seconds - Best dimensional stability among elastomers

- Low curing shrinkage (0.17%)

- Lowest permanent deformation (0.05–0.3%)

- Delay pouring of the model by 1–2 hours if hydrogen gas is present

- Good tear strength (3000 g/cm)

- Highly hydrophobic

- Field must be completely dry

- Some products include surfactants to improve hydrophilicity

- Electroplatable with silver or copper

- Surfactants in hydrophilic variants may reduce electroplating quality

- Low flexibility; harder than polysulfide

- Requires 3 mm spacing in the tray

- Handle cast removal carefully to prevent fracture

- Shelf life: 1–2 years

Manipulation of Addition Silicone Impression Materials

Putty Form

- Equal scoops of base and catalyst are dispensed.

- Mixed by hand kneading using clean fingers until a uniform, streak-free consistency is achieved.

- Latex gloves should not be used (contain sulfur, which retards setting); instead, use vinyl gloves.

Paste Form

- The mixed paste should be spread thinly before loading into the tray to release air bubbles.

- Equal lengths of base and catalyst pastes are placed side-by-side on a mixing pad (in cartridges or tubes).

- A stiff tapered spatula is used for incorporation.

- Mixing time is approximately 45 seconds.

Automatic Mixing (Cartridge Form)

- Comes in double-barrel cartridges with automixing tips.

- Mixing occurs within the tip as the materials pass through internal spirals.

- Large quantities can be mixed with mechanical devices like Pentamix (ESPE), which ensures consistent mix with fewer bubbles and quicker working time.